induction preheating copper bars to temperature

Objective: To preheat two copper bars to temperature within 30 seconds; the client is looking to replace a competitor’s 5kW induction heating system that is delivering unsatisfactory results

Material: Copper bars (1.25” x 0.375” x 3.5”/31mm x 10mm x 89mm )

– Thermal indicating paint

Temperature: 750 ºF (399 ºC)

Frequency: 61 kHz

Equipment : DW-HF- 15kW, 50-150 kHz induction heating power supply with a remote workhead containing two 1.0 μF capacitors

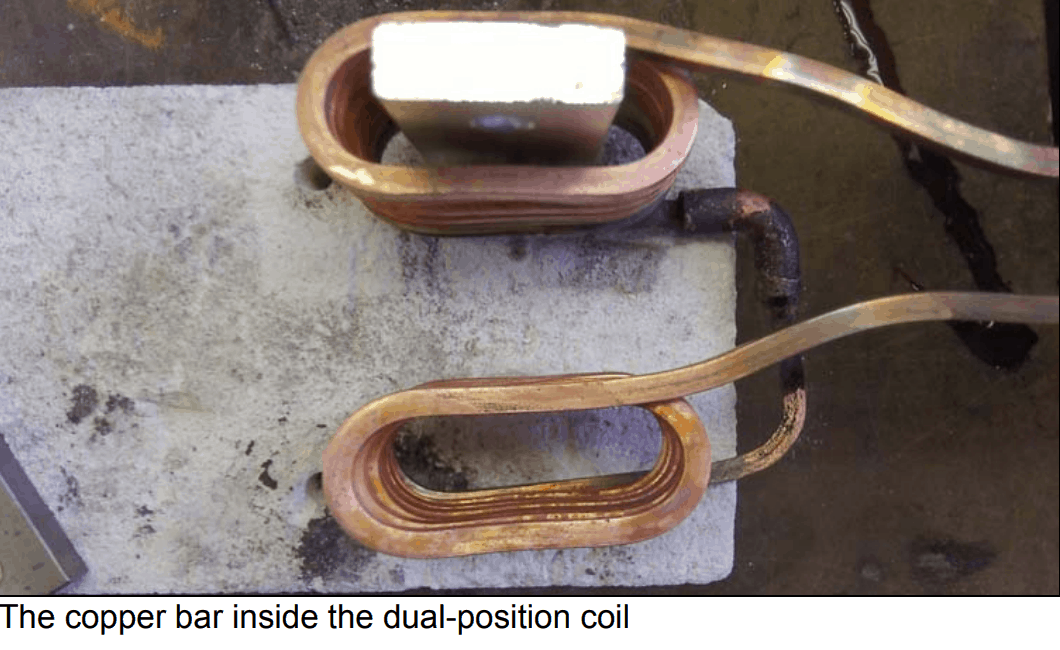

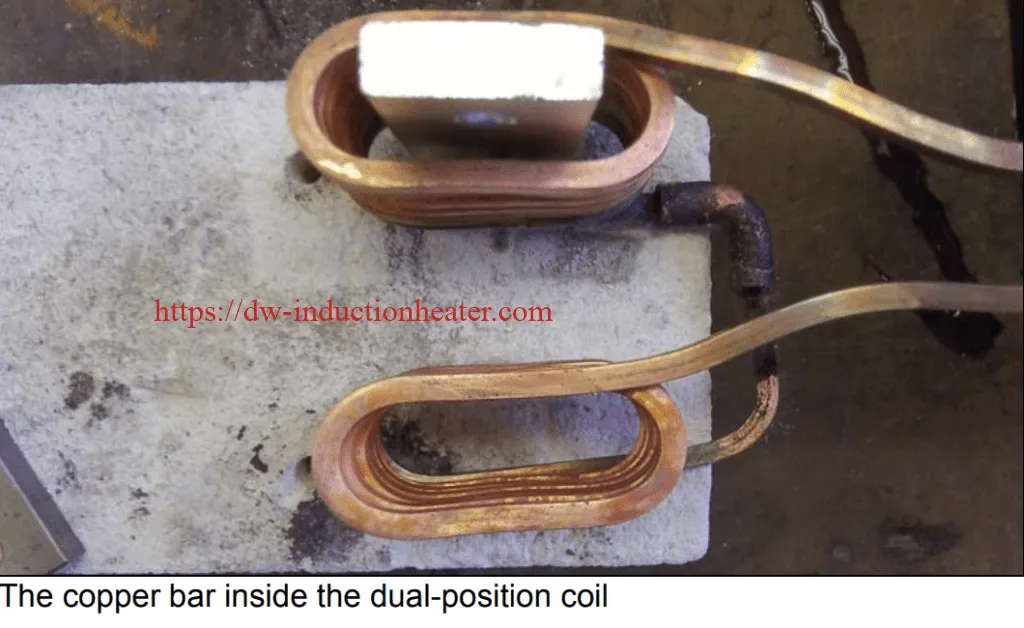

– A dual-position, multi-turn helical coil designed and developed for this heating application

Induction Heating Process: A thermal indicating paint was applied to the face of the copper bar, and the bar was placed inside the coil. The part was heated for 30 seconds and it reached temperature. The next step in the process was to heat two parts in a dual-position coil. The parts were inserted into the coil and heated to temperature within 30 seconds.

In order to heat four parts to temperature within the same time period, two power supplies and two dual-position coils are required.

— Speed: Induction was able to meet their time requirements.

— Process development: The HLQ lab team was able to help the client develop a new heating process that achieved better results than what they saw with their old, inferior induction heating system

— Process efficiency: With induction and the right induction partner, a time, energy and space efficient system was

designed